Our Capabilities

Our staff has over 70 years experience solving challenging corrosion and materials problems in oil and gas pipelines, chemical plants, refineries, paper and tissue mills, bridges, cooling water and boiler water treatment systems.

- Our staff are world recognized experts with over over 100 published papers and over 10 awarded patents.

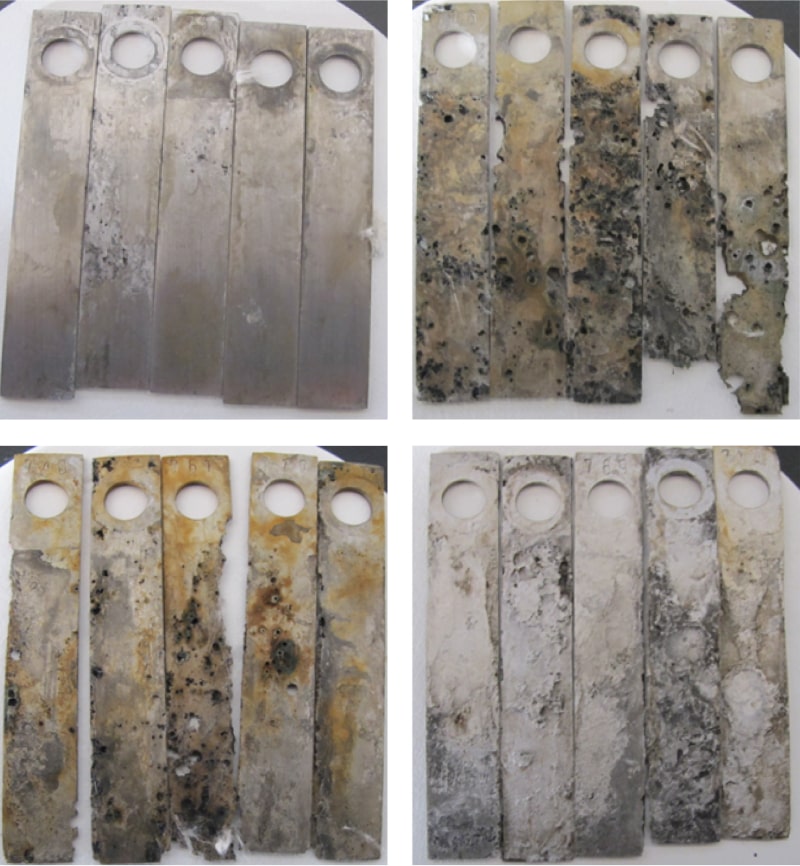

Corrosion Products

Our Customers

Our current and past clients include Kimberly-Clark, Invista (Koch Industries), Chevron, BP, Colonial Pipeline Company, Materials Technology Institute, US Department of Transportation, US Department of Energy, US Navy, CDC, Jiangsu Department of Transportation, Sinopec.

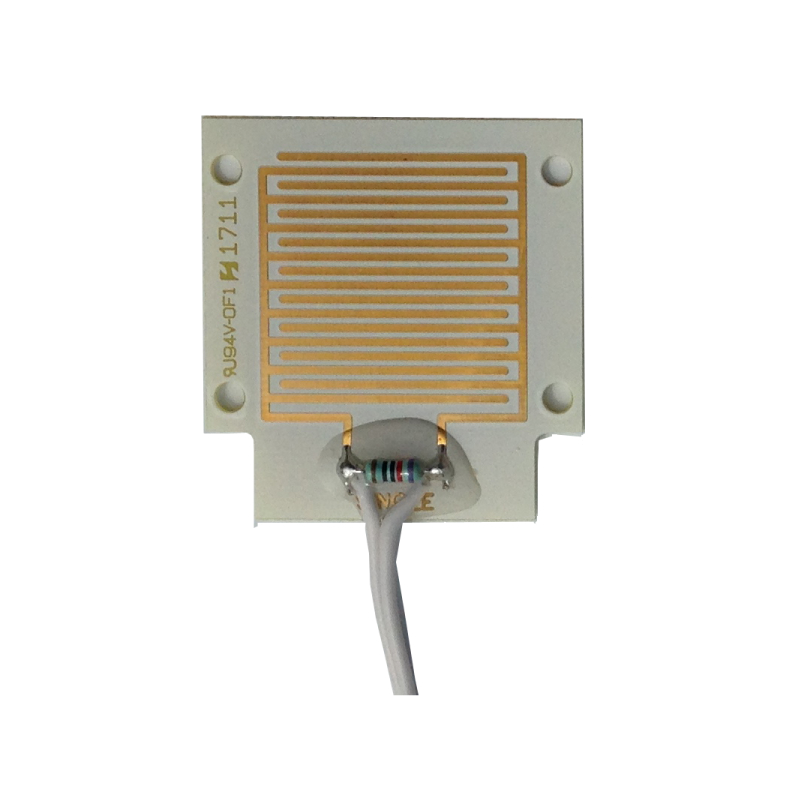

Manufacture,

Sell and Install

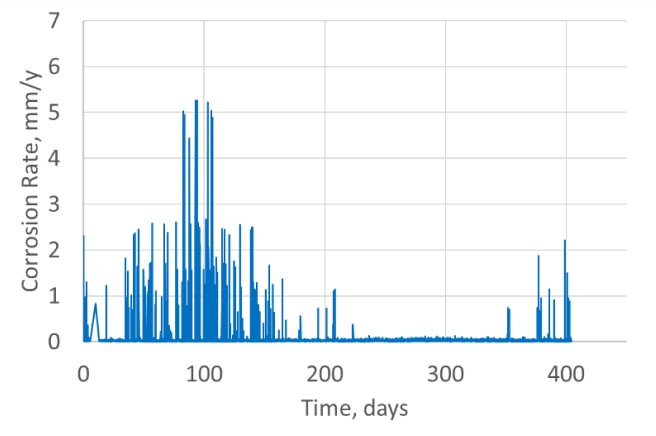

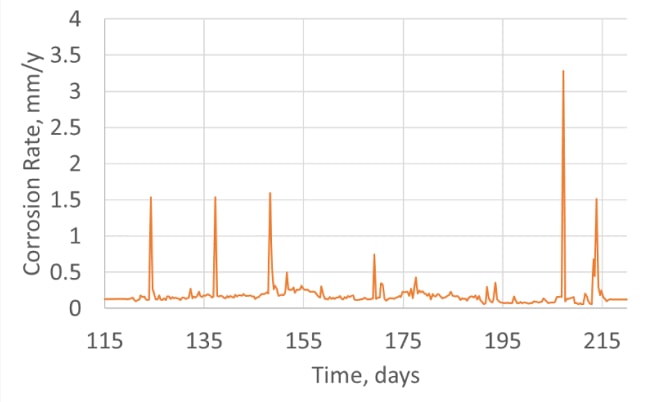

We manufacture, sell and install corrosion coupons, electrical resistance (ER) probes, multiarray sensors (MAS) probes for localized corrosion and MIC monitoring.

Expert Staff

We have trained staff to conduct UT thickness measurements.

Coating and paint condition

Coating and paint condition assessments.

LEAD testing

Lead paint identification testing –

to determine if lead-based paint is present and needs to be mitigated.

Soil and water testing

Soil and water testing for corrosivity and MIC activity – for compliance with PHMSA buried pipeline corrosion assessments and other environmental corrosivity assessments; we follow standardized HACH procedures to measure chloride, sulfate, hardness, carbonate, pH to better characterize soil and water samples.

Drone inspection

Drone visual inspection of facilities and equipment – in lieu of physical visual inspection, we offer drone-based visual inspection was well as IR thermal inspection of facilities and equipment.

Digital maintenance

Digitization of maintenance and operating procedures – we take your paper hardcopy procedures, digitize them and create a tablet/phone-based application to speed up rounds; we have experience linking our systems with others such as SAP to expedite the creation of workorders.

Consulting services

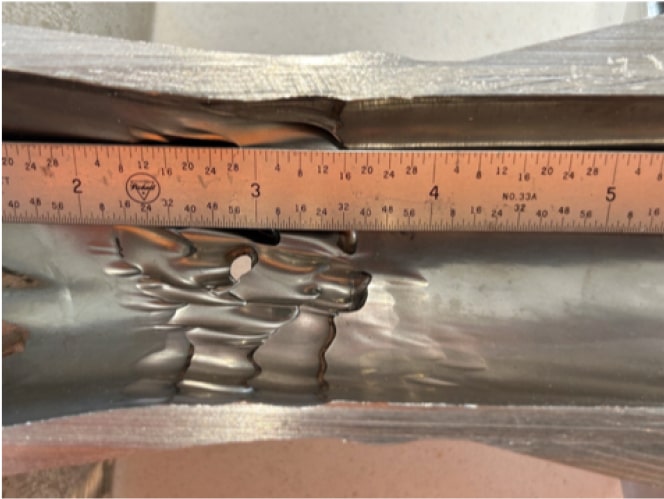

Corrosion and materials consulting including:

- coating and paint specification development

- failure investigations and root cause analyses

- corrosion assessments and P&ID circuitization including inspection method and CML/TML location identification

- Analytics and customized AI solutions to create your own corrosion expert agents

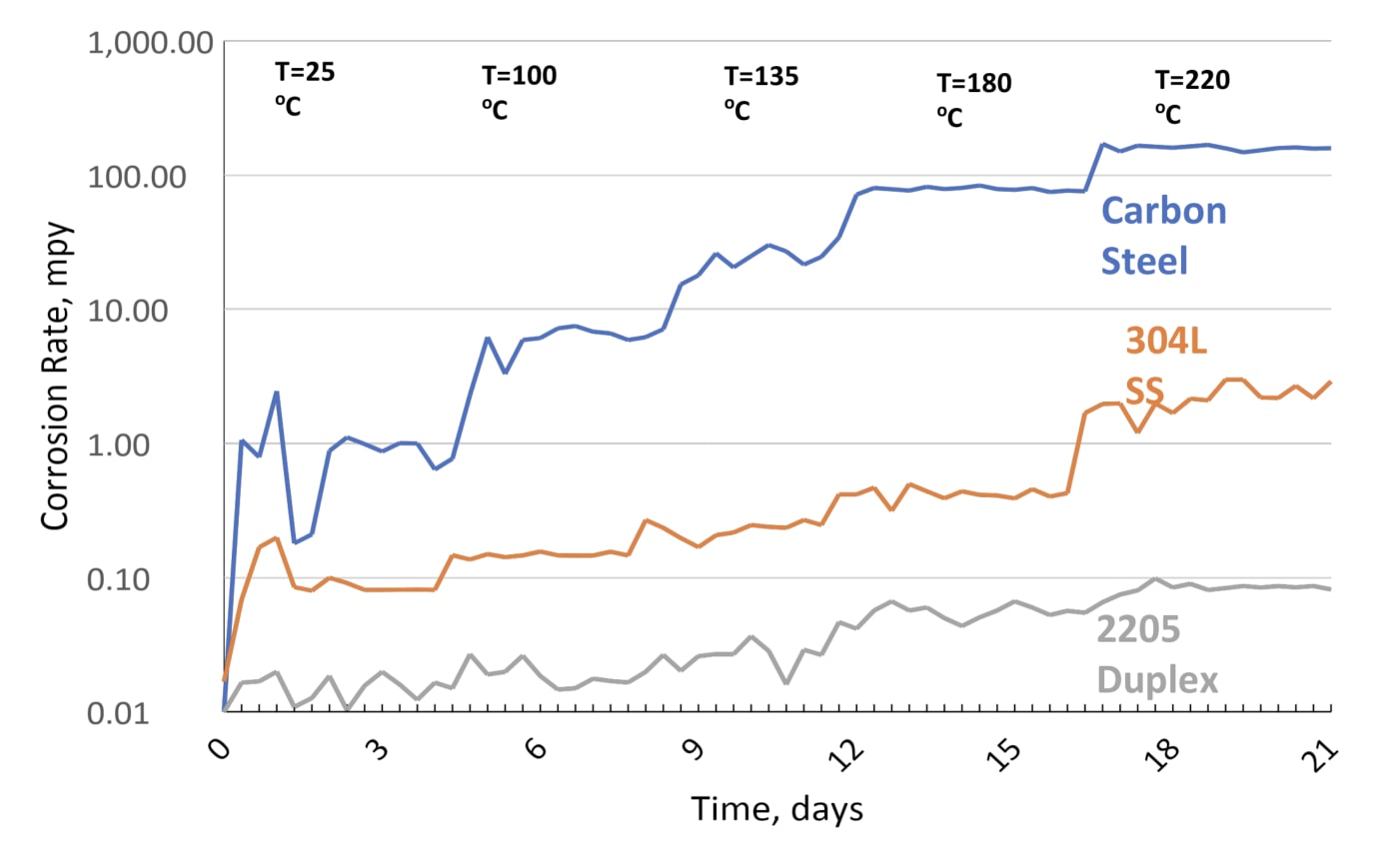

- Materials selection and design including alternate materials of construction and likely life expectancy.